Complete production process in house and complete control in product quality.

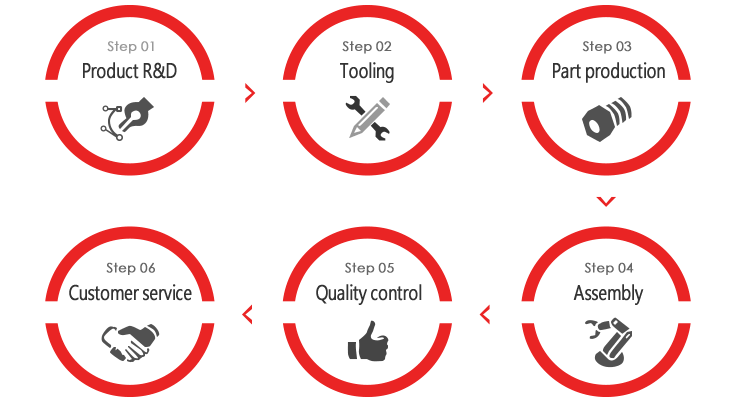

KLS has the complete production process in house in order to control the quality and lead-time while maintaining flexibility for customized requirements. KLS's VDE certified laboratory performs mechanical and electrical tests that always follow UL and IEC standards to assure that product quality is always achieved in production.

Product R&D

The R&D center for terminal blocks and mechanical components is located in Kunshan city, China. With the complete production process in house, the R&D team is able to provide customized service and samples more efficiently.

New patents are granted every year by the KLS R&D team. The technical knowhow is well accumulated in creating satisfactory products that will meet market requirements, which can help us to provide you with professional custom electronics.

The surface treatment is a critical process for terminal blocks because it helps improve resistance to corrosion and conductibility.

Cu, Ni, Sn, Au, Ag, and Zn plating are carried out in KLS factory frequently and customized plating or partial plating is available upon request. KLS strives to provide quality products while meeting tough environment standards set by the local authorities.

Characteristics of the industrial control market include small quantities, large varieties, and short lead-times. In order to respond quicker to the market, three types of production methods (automation assembly, automatic assembly, and manual assembly) are being adopted for different types of product ranges.

The automation assembly line and semi-automatic assembly machines are made by the engineers in the Automation department where every, assembly step is strictly monitored to assure the best results. Manual assembly is the most flexible assembly method and specific fixtures are used to facilitate the production quality and efficiency.

KLS team is here to help you identify your technical needs and provide the solution to your design requirements. KLS's sales team participates in global exhibitions, stays close to the market and understands actual market requirements.

With more than 30 years of engineering experience, the KLS team pays careful attention to each customer's issue and works with the customer to achieve mutual benefits.

Quick Links

Contact Us

Contact Person : Doris

E-mail : sales@klselectronic.com

Tel : +86 574 86828566 86833703

Fax : +86-574-8682-4882

Skype : klssales

Office Add : No. 8-1, Rongxia Rd. Xiapu Shanqian Industrial Zone Beilun Ningbo Zhejiang China 315800